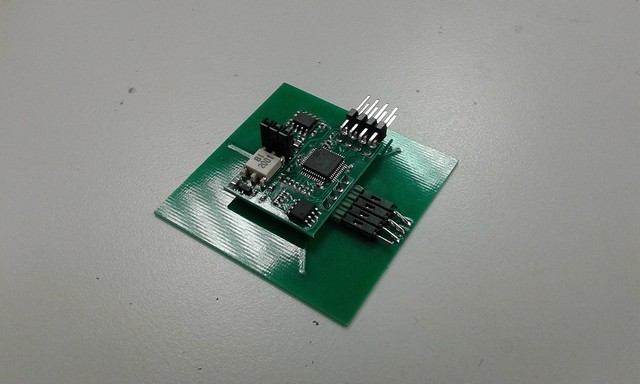

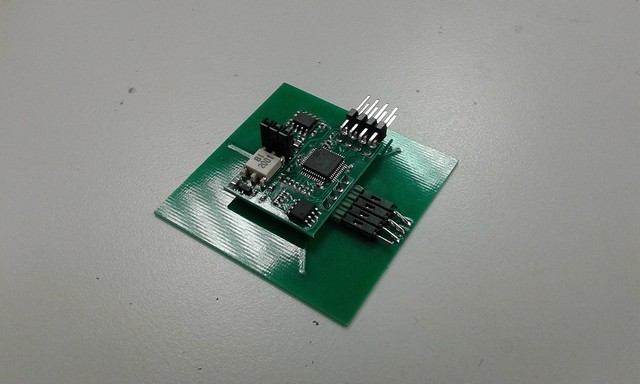

Great news! This afternoon we successfully laser cut our first dummy sensor from the piezo film. Although we had to custom build a pulse width modulator to set the right laser power and find the right focal distance, we managed to obtain a clean, thin cut without overheating the piezoelectric material.